Why Do Some Cars Have Better Clutches? The Factors That Manufacturers Consider

Are you puzzled why some vehicles deliver smoother acceleration and driving experiences than others?

Do you find yourself wondering why clutch performance varies so much between different car models?

The differences in clutch quality stem from various factors that manufacturers meticulously consider during the design and production process.

Understanding these elements can help you make better-informed decisions when it's time to replace your car's clutch or enhance its performance with high-quality clutch kits.

The Role of Clutches in Vehicle Performance

Clutches play a crucial role in vehicle operation by transmitting power from the engine to the drivetrain.

The quality of a car's clutch affects acceleration, efficiency, and overall driving experience.

A well-engineered clutch ensures smooth gear shifts and prevents unnecessary wear and tear on the car’s components.

Given their importance, it's not surprising that manufacturers invest significant effort into designing superior clutches suited for their vehicles.

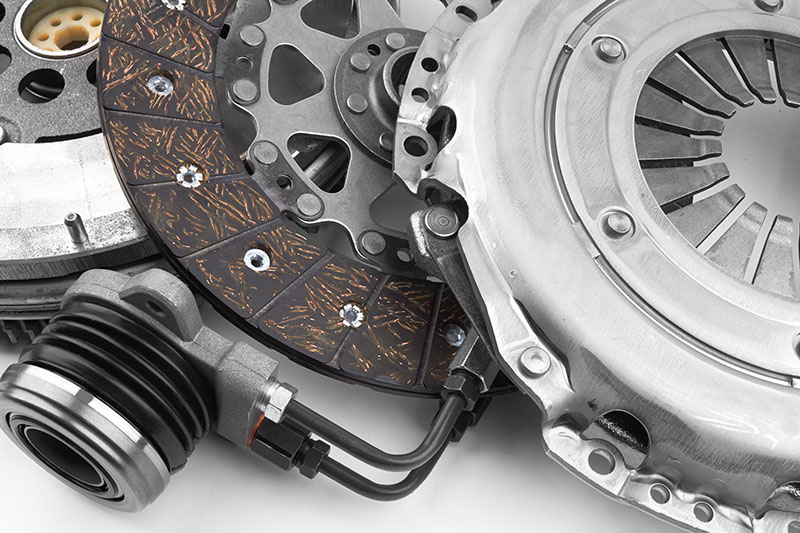

Material Selection in Clutch Kits

Importance of Materials

One of the primary factors influencing clutch performance is the type of materials used.

A range of materials, from organic compounds to kevlar and ceramic, are employed in the fabrication of clutch kits.

These materials have distinct characteristics affecting durability, friction levels, and heat resistance.

Understanding how each material impacts clutch performance is vital for selecting the right kit.

Common Materials

Organic Materials: These are often used in factory-installed clutches.

They are smooth and quiet, ideal for everyday city driving, although they may wear down faster under high strain conditions.

Kevlar: Known for durability and high heat resistance, kevlar is suitable for drivers seeking longevity and higher performance than organic materials can offer.

Ceramic: It handles extreme temperatures and high friction beautifully.

Ceramic clutches are perfect for performance vehicles but may offer a less smooth engagement, making them less suitable for regular street cars.

Clutch Design and Engineering

Types of Clutch Designs

Clutch design significantly impacts its effectiveness and service life.

The three main types of clutch designs are:

Single Plate Clutch: Common in most passenger vehicles, it's usually lighter and simpler, providing a strong grip for smaller engines.

Multi-Plate Clutch: Used in high-performance and racing cars, these have multiple clutch plates to handle greater torque and offer faster gear shifts.

Centrifugal Clutch: Often used in smaller engines like motorcycles and go-karts, engaging automatically at specific speeds, allowing for a more seamless drive.

Engineering Considerations

Manufacturers emphasize the clutch’s ability to dissipate heat generated during its operation.

A clutch releasing excess heat quickly maintains its performance and extends its lifespan.

Additionally, engineers focus on optimizing the pressure plate design to ensure uniform pressure application, leading to consistent performance.

Technological Advancements

Innovations in Clutch Systems

Advancements in automotive technology have led to significant improvements in clutch systems.

Modern vehicles incorporate dual-clutch systems, which use two separate clutches for odd and even gear sets.

This allows for seamless gear changes and quicker acceleration, significantly enhancing performance.

Electronic Assistance

Technologies like electronic clutch actuation have emerged, offering customizable clutch engagement and improved driving dynamics.

These systems enable better control over clutch operation, making it smoother and more responsive for everyday driving and performance applications.

Vehicle Requirements and Manufacturer Specifications

Matching Clutch to Vehicle Characteristics

Every vehicle has unique power and performance specifications, requiring clutches that can effectively manage power distribution without slipping.

Manufacturers meticulously align clutch design with vehicle characteristics, including engine size, torque output, and intended vehicle use.

Manufacturer Specifications

The specifications laid out by manufacturers play a pivotal role in determining clutch design.

These include factors such as:

- Torque Capacity: Ensures the clutch can handle the amount of torque produced without excessive wear.

- Engagement Smoothness: For ultimate comfort and control while driving, clutches should provide a smooth transition.

- Durability: Clutches are designed to withstand the vehicle's anticipated stress tests, influencing material choice and engineering.

Effects of Driving Habits

Driving styles significantly influence clutch life and performance.

Aggressive driving can lead to premature wear and failure, while smooth, steady driving can enhance clutch longevity.

Maintenance Tips

Regular maintenance and timely replacement are essential.

Check the clutch system periodically for signs of wear such as slipping or sticking.

When replacement is necessary, choosing the right clutch kit tailored to your vehicle's needs is crucial to restoring optimal performance.

Environmental Considerations

Impact of Climate

Environmental factors like temperature and humidity can affect clutch performance.

Vehicles operating in hotter climates, for instance, may require clutches that can handle higher temperatures without degrading.

Designing for Durability

Manufacturers design clutches with materials and technologies that withstand various environmental conditions, ensuring reliability across diverse geographical regions.

Performance Requirements

Sport and Performance Applications

Sport and high-performance vehicles demand clutches capable of managing higher levels of stress and thermal loads due to the nature of their operation.

Manufacturers often use advanced materials and technologies in these clutches to boost performance while maintaining longevity.

Customization for Enhanced Performance

For enthusiasts seeking improved driving dynamics, aftermarket clutch kits designed for performance enhancements can be an excellent choice.

These kits offer upgraded materials and designs catering to increased loads and rigorous operating conditions.

Conclusion

Understanding why some cars have better clutches involves looking at a blend of material science, intricate engineering, technological advancements, and manufacturer specifications.

Recognizing the factors that contribute to clutch quality and performance can guide you in choosing the right clutch kit, ensuring your vehicle enjoys smoother, more reliable performance.

Whether you're seeking everyday efficiency or enhanced performance, knowing what goes into clutch design can help you make educated decisions to match your driving preferences and conditions.

|